Quality Control

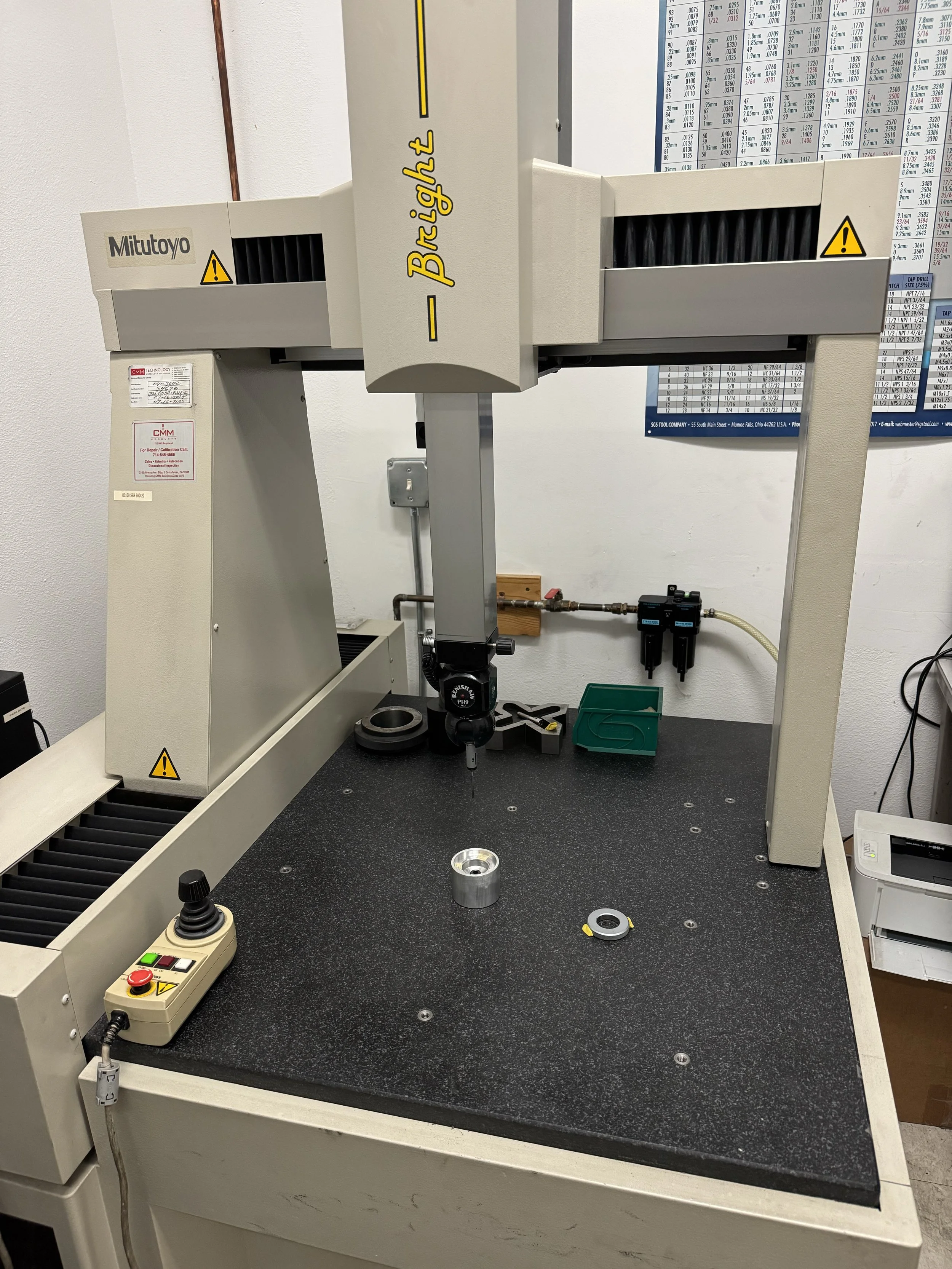

Quality is built into every step of our machining process through disciplined inspection and proven measurement practices. Our inspection capability is anchored by a Mitutoyo 3-axis DCC Coordinate Measuring Machine equipped with a motorized articulating probe head (A/B axes). This is equipped with Nikon CMM Manager software and CAD import, supported by an optical comparator and a full range of precision inspection tools.

Parts are checked at each operation to verify critical features and maintain tight tolerances throughout the job. Complete inspection reports can be provided upon request, giving customers confidence in the accuracy and consistency of every part we deliver.